Cold heading(or cold pressing/ cold forming)

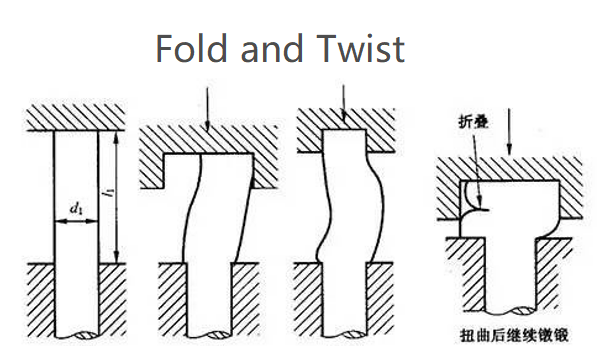

At room temperature, cold heading company place the blank in the cold heading tooling of mold , of an automatic cold heading machine or press, apply pressure to the mold (dies tools etc ), and use the relative movement of the upper punch and lower bottom molds to deform the blank in the cavity, reduce the height, and increase the cross section. Such a pressure processing method is called cold forging for automatic cold forging machines, and cold pressing for cold forming.

In actual production, the cold forming process of fasteners is often accompanied by extrusion in the process of cold heading. Therefore, the cold heading process of fastener products is actually a composite process processing method that includes both cold heading and extrusion.

The cold heading process is one of the few new processes for non-cutting metal pressure machining. It is a processing method that uses the plastic deformation of metal under the action of external force to redistribute and transfer the metal volume with the help of a mold to form the required parts or blanks. The cold heading process is most suitable for the production of standard fasteners such as bolts, screws, nuts, rivets, and pins. The equipment commonly used in the cold heading process is a dedicated cold heading machine. If the production volume is not too large, crank press or friction press can also be used instead.

Cold heading belongs to the forging deformation of smaller workpieces and is often used in the fastener industry. Cold heading is equivalent to a branch of cold extrusion. Simply put, in the process of making bolts, the hexagonal head forming is cold heading, and the rod diameter reduction is cold forging (positive extrusion). Non-trimmed hexagonal flange bolts (multi-station forming) have both cold heading and cold forging. The front side shaping of hexagonal nuts is only cold heading, and the subsequent process of extrusion is cold forging (positive and negative extrusion).

AsiaDies manufacture components of all sizes that are delivered around the world in time to keep production lines running. Our customers are renowned Tier-1 and Tier-2 fastener suppliers as well as inhouse plants of OEM´s of the Automotive industry. We configure intricate, mission-critical assemblies for the machines in which they reside.

Mail info@asiadies.com and ask for more enquire from AsiaDies.com