How the Cold Heading Works

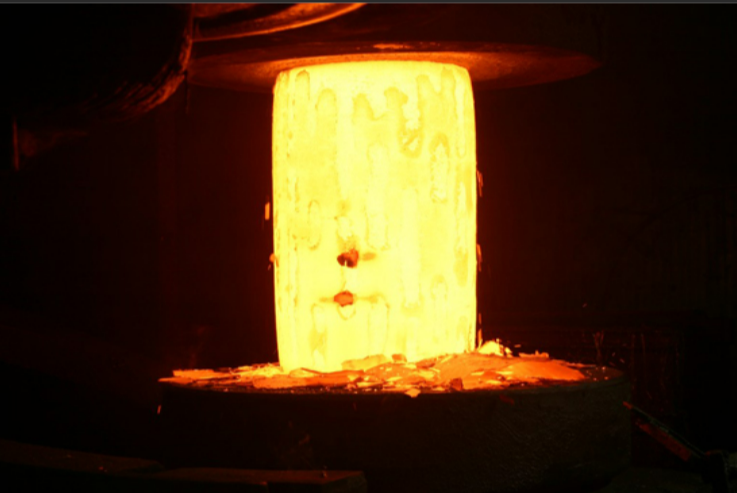

Cold Heading Process

Today we will discuss some tips about the Deformation method of cold heading (cold extrusion).

1、Blanking

cold headed fasteners dies manufacturers will separate a part of the blank from the main body. Such as the cutting of wire, the punching of nuts, the head trimming of hexagon head bolts, etc.

2、Upsetting

The processing method that shortens the height of the blank and increases the cross section, such as the cold heading manufacturing make the upsetting of the nut, the pre-upsetting and fine upsetting of the bolt head forming.

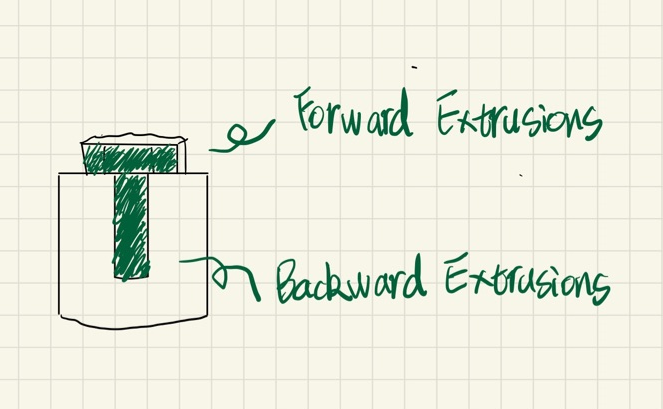

3、Forward Extrusions (Positive Extrusion)

When the blank is deformed in the lower die during cold heading, the flow direction of the metal is consistent with the movement direction of the upper die. The diameter reduction of the thick rod in the cold headed bolt and the cylindrical head hexagon socket screw is a kind of positive extrusion. Such as strong beam (rod).

4、Backward Extrusion (Reverse Extrusion)

During the deformation of the blank, the flow direction of the metal is opposite to the movement direction of the upper die. The head forming of the cylindrical head hexagon socket screw is a back extrusion. Such as deep drawing (hole).

5、Compound Extrusion

Part of the flow direction of the metal during the deformation of the blank is the same as that of the upper die, and part of it is opposite. That is, there are both positive extrusion and reverse extrusion in the deformation. For example, the cylindrical head hexagon socket screw has both rod diameter reduction (positive extrusion) and head forming (reverse extrusion) in the deformation of the same station.

Cold heading was originally used to make fasteners. However, because of today’s technological progress and research, complex cold-headed parts, fasteners and components can be found in thousands of different products and structures around the world, becoming a very important process. The process is constantly improving the process, enabling manufacturers and manufacturers to increase manufacturing profits and reduce costs.

For many years, we have been deeply involved in the manufacture of fastener molds, and our customers are in the automotive, aerospace, medical and other industries. As the industry’s leading and best supplier of cold head molds, AsiaDies fastener molds have unparalleled quality and are specially designed for customer-specific and highly specialized fastener molds. They also have very professional capabilities in the related tungsten steel accessories industry. If your fasteners or components require special things, whether it is material or design, then AsiaDies may be perfect for you. Contact us now to get a quote or ask if cold heading is right for you!